- Otrokovice

- MAXXAN plus s.r.o.

Vizitka v nové práci - strukturovaný životopis, vzor

Co je strukturovaný profesní životopis a proč jej potřebuji?

Životopis - CV (z latinského curriculum vitae, v překladu znamená běh životem) je vaše vizitka, váš první dojem, který u potencionálního nového zaměstnavatele uděláte. Na konci článku najdete životopis zdarma ke stažení.

Klasický životopis je souhrn vašeho vzdělání, vašich pracovních zkušeností, znalostí a dovedností. Slouží budoucímu zaměstnavateli, aby se o vás dozvěděl základní informace, než si vás pozve na osobní (či virtuální) setkání. Jedná se o vaši vizitku, dokument, který je nezbytný pro získání nového zaměstnání.

| Aktuální nabídka práce |

Rozdíly v životopisech

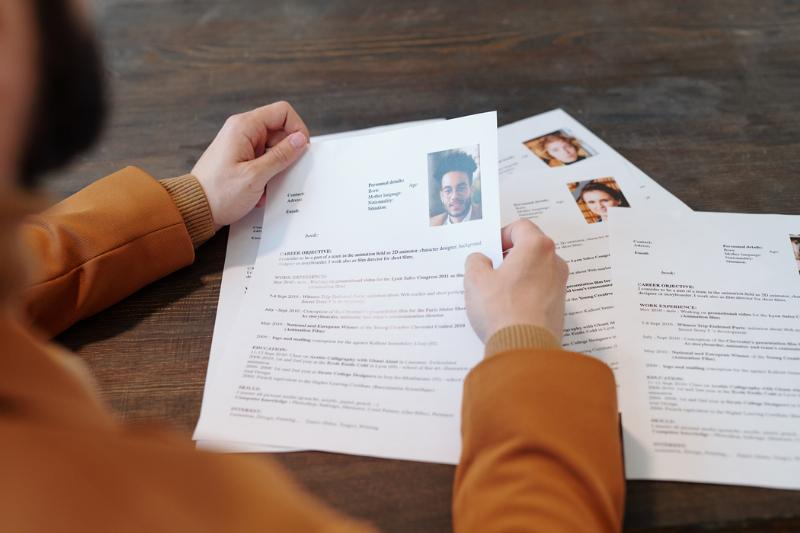

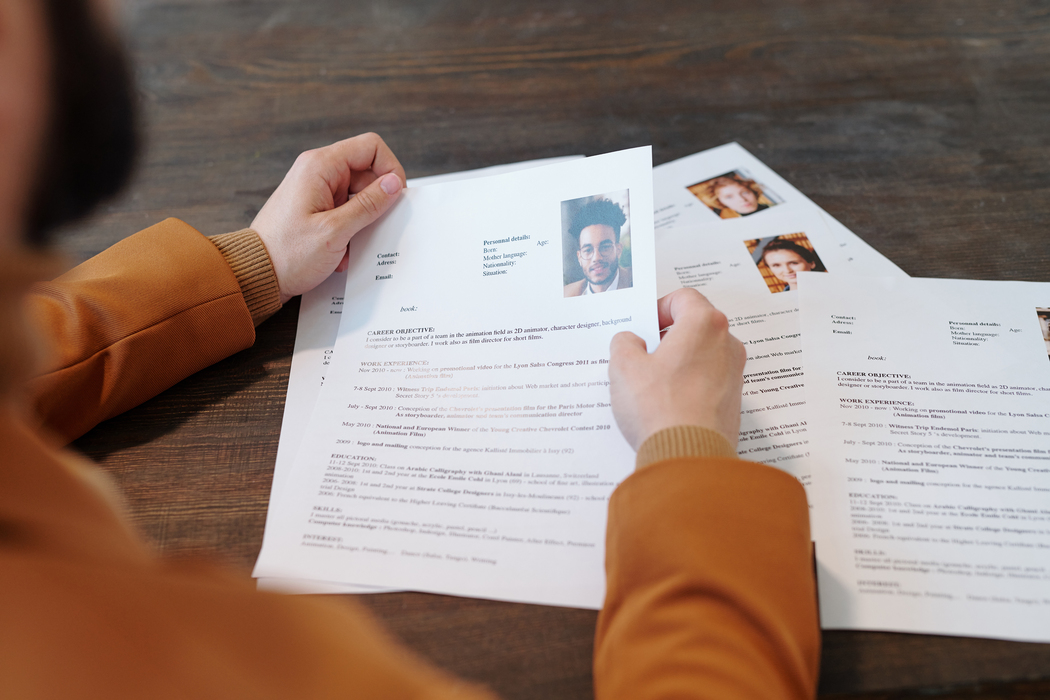

Představte si, že jste personalista a dostanete tyto dva životopisy. Který se vám líbí více?

S tímto životopisem si pan Novák moc práce nedal, mohli bychom ho nazvat nestrukturovaný životopis vzor, ukázka níže:

xxx@xxx.xx

123 123 123

od 2020 skladník v expediční společnosti - přemisťování palet, inventura, lepení štítků, nakládka a vykládka kamionů, inventura

angličtina - OK

PC - OK

Pan Novák poskytl stejné informace v upraveném formátu a posílá tak do nové práce téměř vzorový životopis:

Email: xxx@xxx.xx

Telefon: 123 123 123

Zkušený skladník se smyslem pro detail a zápalem pro svou práci.

2020 - stále

Expediční společnost - Skladník

Hlavní zodpovědnosti:

manipulace s paletami,

inventura zboží,

štítkování zboží,

nakládka a vykládka kamionů,

inventura zboží.

Jazykové znalosti:

Anglický jazyk - střední úroveň, B2

Technické dovednosti:

MS Office - uživatelská znalost

Doplňující informace:

Řidičský průkaz skupiny B

Řidičský průkaz na vysokozdvižný vozík

I tento druhý příklad životopisu se může vylepšit, každopádně už nyní je rozdíl velký. A pro zmíněného personalistu je jednodušší vybrat, se kterým uchazečem se setká.

Pojďme si ukázat, jak vytvořit životopis, který zaujme na první pohled nebo si sestavte životopis online během krátké chvíle a odešlete jej na některou z našich nabídek zaměstnání:

- Přejděte na tento odkaz.

- Zaregistrujte se na našich stránkách.

- V levém menu vyberte možnost “Životopis”.

- Klikněte na červené tlačítko “Vytvořit životopis”.

- Nechte se vést jednotlivými kroky v jednoduchém formuláři.

| Vytvořit životopis |

Tipy a triky pro tvorbu profesního strukturovaného životopisu, se kterým zaujmete

Tvorba životopisu, který bude za něco stát, zabere čas a je vhodné se nad ní pořádně zamyslet. Naše tipy a triky vám pomohou s vytvořením životopisu, který vás dostane do vysněné firmy.

Jak podrobný životopis bude, záleží na vašich znalostech a zkušenostech. Není třeba vypisovat všechny detaily, držte se základních údajů a úspěchů. Detaily můžete na vyžádání sdělit na pohovoru.

- Výběr písma - používejte jeden druh písma v celém životopise, je možné zvýraznit pozici, kterou jste zastávali, nebo kurzy, které jsou pro pozici, na kterou se hlásíte, relevantní.

- Odolejte pokušení a nepoužívejte neobvyklé druhy písma, které dokument nabízí.

- Odolejte pokušení a nepoužívejte neobvyklé druhy písma, které dokument nabízí.

- Odrážky - pro lepší přehlednost zvolte odrážky, když budete popisovat své zkušenosti a znalosti.

- Nepoužívejte dlouhé věty, slohová cvičení bude s chutí číst málokdo.

- Zkratky, firemní "hantýrka" - vyvarujte se používání zkratek a firemních výrazů, které nejsou všeobecně známé a používané.

- DPMHK - každý si pod touto zkratkou může představit něco jiného (mimochodem, je to zkratka pro Dopravní podnik města Hradec Králové).

- Pouze pravda - ve svém životopise uvádějte jen pravdivé informace, například úroveň angličtiny či počítačové dovednosti se často na pohovorech testují.

- Dříve nebo později by se na nepravdu přišlo a přineslo by vám to jen komplikace. Když něco neumíte, doučíte se to!

- Gramatika - vytvořený pracovní životopis si po sobě přečtěte, využijte funkci kontroly pravopisu v MS Word, nebo požádejte někoho o kontrolu.

- Personalista nebo manažer, který si otevře životopis, a uvidí gramatické hrubky, nebude chtít číst dále.

- Finální dokument - finální verzi životopisu si vytiskněte, překontrolujte vizuální podobu, přehlednost a požádejte někoho z blízkých o kontrolu a zpětnou vazbu. Finální verzi uložte do formátu PDF, který působí profesionálně. Životopis uložte například ve formátu příjmení_jméno_CV / životopis.PDF

Pokud je inzerát, na který odpovídáte, v angličtině, nebo je anglická verze životopisu vyžadována, pošlete pouze požadovanou anglickou verzi životopisu.

Jak napsat životopis strukturovaný profesionální, který zaujme, mám vložit fotku, mám uvést vzdělání do životopisu, mám uvést zájmy a koníčky do životopisu? Na všechny otázky odpovíme v článku Vše o životopisu, profesní životopis vzor v češtině a angličtině zdarma.

Chcete si vytvořit moderní životopis? Jistě můžete. Jen zvažte, do jaké společnosti a na jakou pozici jej budete posílat. Do banky na pozici bankovního úředníka doporučujeme klasický strukturovaný profesní životopis. Na pozici fotografa nebo design specialisty můžete popustit uzdu své fantazii a s formou životopisu si vyhrát, s tím, že dodržíte pravidla popsaná výše.

| Aktuální nabídka práce |

Vzor klasického strukturovaného životopisu v češtině i angličtině ke stažení zdarma

Vytvoření životopisu zdarma podle předlohy či formuláře? S námi si můžete vytvořit strukturovaný životopis podle šablony ke stažení, kterou naleznete v níže uvedeném odkazu. Jedná se o formulář životopisu, který si můžete přizpůsobit. Nedáváme vám klasický strukturovaný životopis (vzor) v PDF, ale v plně editovatelné podobě.

Klasický životopis vzor / šablona ke stažení v češtině zdarma.

Klasický životopis vzor / šablona ke stažení v angličtině zdarma.

Máte připravený životopis! Už jste jen krok od toho, abyste vysněnému zaměstnavateli mohli odpovědět na jeho inzerát. Pojďme si připravit motivační dopis, který doplní váš životopis a průvodní dopis, který by neměl nikdy chybět.

Publikováno 11. dubna 2022

Další rozhovory a články z poradny JenPráce.cz

Co personalista musí znát o odborové organizaci

Získejte základní přehled o odborech, ať již ve vaší společnosti působí odborová organizace, nebo předpokládáte, že bude v dohledné době založena. Shrnuli jsme základní informace o tom, co to je odborová organizace a jaké má vůči ní zaměstnavatel…

Zaměstnavatel nechce převzít výpověď

Ukážeme vám, kdo může ve společnosti výpověď převzít, a dva způsoby, jak si nechat přijetí výpovědi zaměstnavatelem potvrdit. Poradíme vám, jak postupovat, pokud váš zaměstnavatel odmítl převzít výpověď.

Jak správně změnit délku pracovní doby

Potřebujete zaměstnanci změnit pracovní dobu? Pokud je pracovní doba součástí pracovní smlouvy, potřebujete souhlas dotčeného zaměstnance. Je-li pracovní doba určena vnitřní směrnicí, můžete délku pracovní doby změnit. Pojďte se s námi na jednotlivé…

Doporučující dopis od zaměstnavatele

Doporučující dopis do zaměstnání může být klíčový při rozhodování vašeho nového zaměstnavatele. Z dopisu zjistí, jaké jsou vaše silné stránky, na jakých projektech jste pracovali, jak jste zapadli do současného týmu a mnohem více.

Výhody a nevýhody sdíleného pracovního místa

Víte, že novela zákoníku práce přinesla sdílené pracovní místo? Sdílení pracovního místa znamená, že minimálně dva zaměstnanci se střídají na stejném pracovním místě a dohromady svými částečnými úvazky pokryjí pracovní úvazek celý. Představíme vám…

Vaše práva při zrušení dovolené zaměstnavatelem

Zaměstnavatel určuje čerpání dovolené svých zaměstnanců. Zjistěte, kdy může zaměstnavatel zrušit dovolenou, i tu, kterou již máte zaplacenou, nebo vás v průběhu dovolené z ní odvolat zpět do práce. Ukážeme vám, co všechno následně zaměstnavatel musí…

Co dělat, když vám zaměstnavatel nezaplatil

Poradíme vám, co dělat, když zaměstnavatel neplatí mzdu a co dělat, když zaměstnavatel neplatí sociální a zdravotní pojištění. Nevyplacená nemocenská? I s tím vám poradíme. Dozvíte se také, jak správně podat stížnost na zaměstnavatele.

Půjčka zaměstnanci jako benefit společnosti

Zvažujete nový benefit pro své zaměstnance? Co například půjčka pro zaměstnance! Zjistěte, jaké typy půjček můžete zaměstnancům poskytnout, jaké jsou daňové dopady jednotlivých typů půjček.

Jak podat insolvenční návrh na zaměstnavatele

Poradíme vám, jak podat insolvenční návrh na zaměstnavatele, který vám například nevyplácí vaši mzdu nebo odstupné. Máte dvě možnosti, jak své peníze získat zpět. V článku najdete i vzor insolvenčního návrhu.

Proč mít připravenou pracovní náplň + VZOR

Pracovní náplň, se kterou zaměstnance prokazatelně seznámíte, vám pomůže s určením konkrétních povinností, které má zaměstnanec zastávat. Poradíme, kdo pracovní náplň připravuje, v jakých případech ji může zaměstnavatel změnit či doplnit. Získáte…

Dvě zaměstnání současně - daně, nemocenská

Chcete si přivydělat a máte dvě zaměstnání? Můžete mít ke své pracovní smlouvě uzavřenou dohodu u svého stávajícího zaměstnavatele, pokud práce na dohodu bude jiná než ta, kterou děláte na základě pracovní smlouvy. Nebo můžete mít zaměstnavatele dva…